ABOUT US

Established in 1995, Bulplast-M EOOD specializes in the production of individual polyethylene solutions for the needs of your business. Our modern production base in Vratsa offers industrial HDPE and LDPE polyethylene bags and sacks for product packaging, polyethylene sleeves, half-sleeves and tapes, shrink and stretch film, as well as advertising bags with flexo printing in up to six colors. Thanks to our environmental protection program, we recycle a large part of our production. Bulplast-M EOOD - our name is a guarantee of quality and reliability!

OUR PHILOSOPHY

We believe in the individual approach to find a solution for the needs of each client and we will find the optimal solution for your business. This is the only way we can guarantee flexible production, express deliveries and high product quality.

OUR MISSION

High-quality industrial production and environmental protection. Our goal is the elimination of secondary pollution through the complete closure of the production cycle, through the effective application of the most advanced technologies in recycling.

OUR VISION

We strive for a world free of secondary waste and relying on renewable energies for its needs. We believe that with a lot of work, modern technology and responsibility, we can make the world we live in a cleaner place.

Our solutions

The optimization of the production process and the visual presentation of the product are a key to every success. Therefore we are offering you individually made products, which fully correspond to the needs of your business. Our custom-made manufacture will contribute maximum efficiency during the packaging process and presentation of your product, saving you time and valuable resources.

Our services

Free consultation

We will gladly help you to find the best solution for your business. Call us for a free consultation!

Free print design

We are offering you free print design for your order!

Free product samples

Order your free product samples! Delivery is free for the territory of Bulgaria!

FREE DElivery

We will deliver your order door to door in the region of Sofia!

Production process

Production process

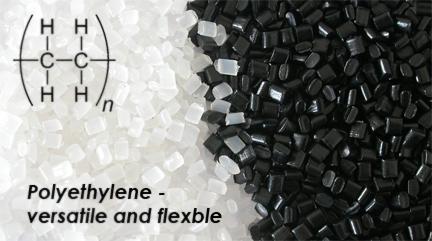

Raw Materials

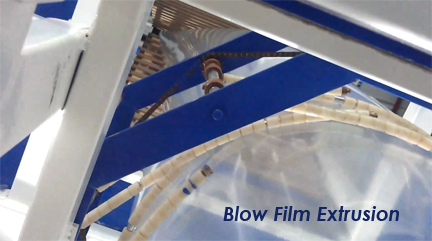

Extrusion

Folding

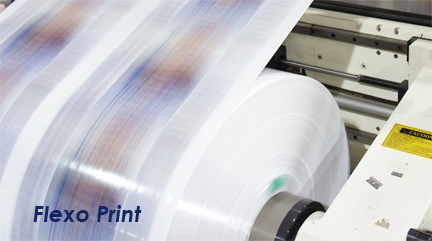

Flexo Print

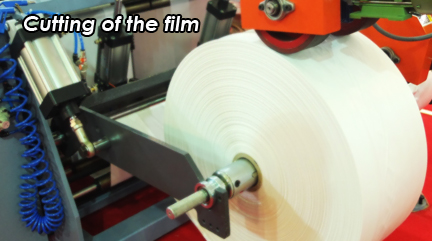

Cutting

Recycling

High-density polyethylene (HDPE) and Low-density polyethylene (LDPE) are polyethylene thermoplastics made from petroleum. LDPE has low-density levels and only a small amount of branching. It is very flexible and easy to clean and is often used to make plastic film wrap and plastic bags. HDPE has higher density levels and has a linear structure consisting of no branching. That makes HDPE stronger and more resistant to chemicals. The raw materials used by us have high quality and excellent molding properties.

Extrusion is the first step in the production process of polyethylene. The raw materials (HDPE and LDPE) are in the form of granules, which melt under high temperature and are “blown” in a balloon-like form. This is followed by cooling down and rolling of the now ready polyethylene film. According to the customer requirements, the color of the extruded film could be changed via additives, known as “master batch”. We assure the high quality of our production throughout this complex process via strict quality control, investment in new technologies and improving the skills of our employees.

Depending on the customer’s needs, the extruded polyethylene film can be folded in order to form specific bottom or side folds via a special machine. The semi-sleeves, films, carry bags and sacks formed in this fashion have various industrial applications. High quality color images could be printed on the folded product via flexo print.

Before the roles with extruded polyethylene film enter the printing process, it is necessary to prepare the print design - our designers will offer you the perfect solution for your order. The print design is then transferred on approved and ordered photopolymer plates. We are offering you flexo print with up to 6 colors on our products. The flexo print allows the printing of high quality color images on the polyethylene film.

The polyethylene film is cut into various bags or sacks depending on the demand. The client determines the amount of cut products that every package contains. We offer: bags and sacks with side seam bags and sacks with bottom and side seal bags with lip with or without tape bags and sacks with perforation corrugated bags and sacks T-shirt carry bags Die-cut carry bags with enforced handles

Recycling is the last step of our production cycle. Unlike paper, polyethylene products and particularly HDPE and LDPE, can be recycled over and over. The plastic waste, generated through production is transformed back into granules and is used for creating new products. In this way we close the production cycle and reduce the environmental impact of our production.

WHY CHOOSE US?

Solutions

Individual solutions from polyethylene created for the needs of your business

Products

High quality sleeves, films, bags, sacks and advertising carry bags from polyethylene

Offers

Order your individual advertising carry bags for only 219 BGN without VAT!

Process

With regard to nature – meet our production process

Innovations

New! Corrugated bags with industrial application for more stable transportation

QUALITY

We pride ourselves on offering our customers the highest quality products and service